Continuous Process Improvement (CPI) Toolkit

What is Continuous Process Improvement (CPI)?

Continuous process improvement is the ongoing improvement of services or business processes using an incremental approach focused on continuously reviewing results and rapidly adopting new measures when necessary.

Why is DFA fostering a culture of CPI?

By prioritizing CPI, we are cultivating a collaborative environment where employees are encouraged to think innovatively in order to streamline processes, leading to increased efficiencies and ultimately better business outcomes. CPI yields higher employee engagement levels and will enable units to gain efficiencies, which is critical due to the growing demands on our workforce. Additionally, this equips us to respond effectively to ongoing and emerging changes and opportunities, ensuring the long-term success of our organization.

Who is responsible for CPI?

CPI is everyone’s responsibility! The role of front-line employees is especially critical as they are aware of the problems in the process most directly. A large study by Sidney Yoshida indicates that only 4% of problems faced by an organization are known to top managers, 9% of problems are known to middle management, 74% of problems are known to supervisors, and 100% of problems are known to front-line employees. Identifying a bottleneck in the process, bringing it up to your supervisor or manager, and working together with your team to resolve it, is a proven recipe for success and the responsibility of every front-line employee. The responsibility of managers and supervisors, likewise, is to remain curious and champion continuous process improvement projects within their teams.

How are we supporting a culture of CPI in DFA?

|

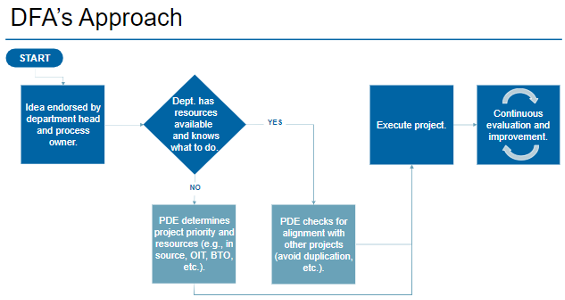

Continuous process improvement is an essential part of DFA’s strategy. Embedded in our approach to operations is a deliberate emphasis on enhancing processes through the dual lenses of effectiveness and efficiency, which are among our divisional values. DFA Program Development and Execution (DFA-PDE) team supports all DFA units in their continuous process improvement efforts by making available tools, templates and trainings covering Lean Six Sigma, project management, and change management key concepts and topics. Additionally, DFA-PDE facilitates a centralized approach to continuous process improvement in DFA to ensure project alignment with divisional strategy, foster collaboration among units in cross-functional projects, and streamline the management of the various CPI projects and initiatives. If you have any questions about DFA’s approach to CPI, please email WithUForU@uci.edu. |

|

Tools/Training

Lean Six Sigma (LSS) is a systematic approach to process improvement, combining two methodologies - Lean, which focuses on removing waste and increasing speed and efficiency, and Six Sigma, which aims to reduce defects and variation in processes, and increase quality, accuracy, and effectiveness. Various LSS tools can be used independently and in combination to assist in planning and managing process improvement projects.

Project management (PM) is the application of specific knowledge, skills, methods, and techniques to achieve project objectives within specified constraints, including timeline, budget, etc. It offers tools and templates to initiate, plan and execute projects, including managing scope, schedule, budget, risks, communications, etc.

Change management (CM) is an enabling framework for managing the people side of change and prepare, equip and support individuals so they can successfully adopt the changes. It offers approaches and tools to effectively deal with transitions, including strategies for effecting change and empowering people to adapt and thrive.